More Calibration Services Companies

A calibration device is an essential, specialized tool that uses precise electrical signals to fine-tune and standardize the performance of instruments or equipment, ensuring they operate within highly accurate, predefined parameters. This process is indispensable in industries where measurement accuracy, regulatory compliance, and safety are non-negotiable—such as manufacturing calibration, healthcare calibration, pharmaceutical equipment calibration, aerospace calibration services, and scientific research instrument calibration.

Calibration begins with a detailed assessment of the device under test (DUT) to determine its error margin—the deviation between its current output and the expected or reference value. Using the calibration device, which generates controlled signals like voltage, current, or frequency, technicians adjust the DUT’s settings—either via advanced software interfaces or manual controls—so its performance aligns with the original manufacturer’s specifications and industry standards. This precise adjustment not only enhances the instrument’s reliability, repeatability, and accuracy but also minimizes errors that could otherwise compromise outcomes. For example, a miscalibrated sensor in a medical diagnostic device could result in false readings with critical consequences.

Are you searching for how to calibrate industrial equipment, where to find certified calibration services, or reliable calibration labs near me? Read on for a comprehensive guide to calibration devices, service applications, benefits, decision factors, and how to choose the best calibration provider for your needs.

Understanding the Calibration Process: Traceability and Standards

The calibration process is methodical and evidence-driven. It involves a direct comparison between the DUT and a traceable reference standard—a benchmark of known, certified accuracy. These standards, often certified by organizations like the National Institute of Standards and Technology (NIST) or UKAS in the UK, serve as the gold standard for measurement. For example, a NIST-certified voltage source may provide a reference value of exactly 5.000 volts. If the DUT reads 4.98 volts, the discrepancy is quantified and corrected through mechanical, electronic, or software adjustments. This ensures the DUT operates within an acceptable tolerance range, as defined by industry regulations or quality management systems (QMS) like ISO 9001 or ISO/IEC 17025.

Wondering why calibration traceability matters? Traceability guarantees that your measurements can be linked to recognized national or international standards, providing confidence in your data and compliance during audits or inspections.

Calibration Service Applications: Where Is Calibration Used?

Calibration services are critical across a broad spectrum of industries and applications, ensuring that standardized instruments deliver accurate, trustworthy results. In both industrial and laboratory environments, devices that measure pressure, temperature, speed, mass, and other key variables must be meticulously calibrated to maintain operational efficiency, compliance, and product quality.

Typical instruments and sensors requiring routine calibration include:

- Load cells and scales—for weighing applications in logistics, laboratories, and manufacturing.

- Data acquisition sensors—monitoring critical process variables in automation and industrial control systems.

- Temperature sensors—such as thermocouples, RTDs, and thermistors in food processing, HVAC, and biotech.

- Chemical sensors—used for environmental monitoring, water quality, and laboratory analysis.

- Strain gauges—for structural testing and materials research.

- Automotive sensors—including mass airflow, wheel speed, fuel level, and airbag sensors.

- Proximity sensors and optical sensors—like fiber optic sensors and photon counters in manufacturing and research.

- Temperature gauges—such as thermometers and pyrometers for industrial furnaces and clinical labs.

- Navigational instruments, Geiger counters, barometers, and more.

Looking for calibration solutions for your specific industry? Contact an accredited calibration service provider to discuss your application.

History and Evolution of Calibration

The science of calibration has deep historical roots, beginning with humanity’s earliest attempts to establish standardized weights and measures. In ancient times, units like the cubit were based on the length of a forearm, leading to inconsistent results. Landmark events—such as the Assize of Measures in 1196 and the Magna Carta in 1215—formalized standards for length and volume, setting the stage for a culture of measurement consistency.

The Renaissance and Industrial Revolution saw the invention of complex measurement tools, such as Torricelli’s mercury barometer (1643), driving demand for higher precision and the formal adoption of calibration practices. The term “calibrate” emerged during the Civil War, initially referring to firearm barrel and ammunition measurements, before expanding to broader scientific and industrial contexts.

By the 20th century, the need for precision in sectors like oil and gas, automotive manufacturing, aerospace, and life sciences led to the formation of global standards organizations, including the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO). Today, U.S. regulations continue to evolve, with agencies like NIST overseeing national calibration and performance standards to ensure safety, efficiency, and global competitiveness.

Recent advances in electronics and digital technology have revolutionized calibration, enabling real-time, highly accurate adjustment of even the most complex sensors and transducers. Automated calibration systems, digital twins, and cloud-based calibration data management are now mainstream, drastically reducing the margin of error compared to manual methods.

What are the Industrial Machine Calibration Service Procedures?

Industrial machine calibration procedures are rigorous, standardized workflows designed to verify and adjust equipment performance to meet exacting standards. Whether calibrating CNC machines, pressure gauges, robotic arms, or pharmaceutical processing equipment, the goal is consistent, traceable accuracy. Here’s a step-by-step overview of typical calibration service procedures:

- Preparation and Planning

- Equipment Assessment: Review equipment type, application, calibration history, and applicable standards (e.g., ISO 17025, NIST traceability).

- Tool Selection: Choose certified calibration devices (multimeters, signal generators, deadweight testers) with higher precision than the DUT.

- Environmental Control: Maintain stable lab conditions (e.g., 20°C ± 2°C, controlled humidity) to eliminate environmental variables.

- Initial Inspection and Testing

- Visual Check: Inspect for physical damage, contamination, or wear that could affect results.

- As-Found Test: Record DUT performance using the calibration device before any adjustments—sets the baseline.

- Comparison to Reference Standards

- Reference Setup: Introduce traceable standards (e.g., NIST-certified weights, voltage sources).

- Measurement Comparison: Compare DUT outputs at multiple set points and log discrepancies.

- Adjustment and Calibration

- Error Correction: Adjust the DUT via mechanical, software, or component replacement methods until within required tolerances.

- Re-Test: Confirm post-adjustment results (as-left data) match standards within specified uncertainty limits.

- Documentation and Certification

- Calibration Report: Document all test data, standards used, environmental conditions, and technician details.

- Labeling: Affix calibration stickers with the date, due date, and any relevant compliance notes.

- Compliance: Ensure records meet ISO 9001, FDA, or other regulatory requirements for audit readiness.

- Post-Calibration Verification

- Functional Check: Test the machine in its real-world context to confirm accurate operation.

- Scheduling: Establish recalibration intervals based on criticality, usage, and regulatory needs (monthly, quarterly, annually, etc.).

Industry Nuances:

- Aerospace calibration often requires sub-micron precision and automated, repeatable calibration rigs.

- Pharmaceutical calibration must satisfy GMP and FDA requirements, with full traceability and documented processes.

- Heavy industry favors rugged, portable calibration equipment for on-site, field-ready service.

Curious about how often your equipment should be recalibrated? Ask a calibration expert for recommendations based on your industry, regulatory environment, and usage patterns.

Calibration Machinery and Equipment Types

Professional calibration service providers use a wide range of calibration equipment and tools, tailored to the type of instrument and required precision:

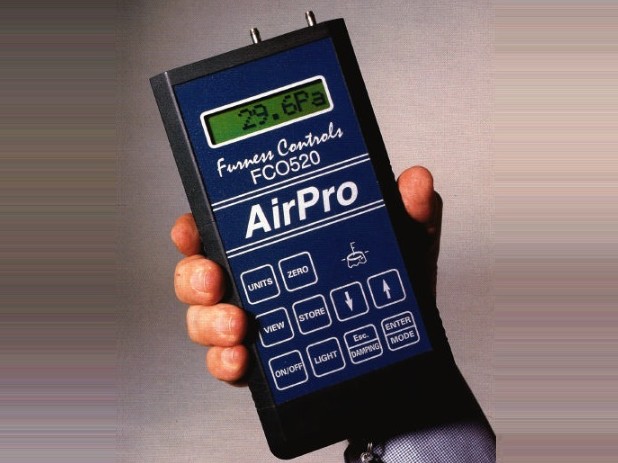

- Handheld calibrators: Compact, battery-powered tools for field or lab calibration (e.g., loop calibrators, portable pressure calibrators).

- Stationary calibration systems: Lab-based reference instruments, often integrated into fixed test benches for high-volume or high-precision calibration (e.g., deadweight testers, reference multimeters).

- Mobile calibration units: Portable, often wheeled systems for on-site calibration of large or immobile equipment in factories or plants.

- Automated calibration rigs: Computer-controlled systems for high-throughput, repeatable calibration—ideal for mass production, aerospace, or automotive manufacturing.

Looking for advice on which calibration equipment suits your needs? Speak to a calibration consultant for recommendations based on your equipment inventory and usage.

Variations of Calibration Processes and Specialized Services

Calibration is not one-size-fits-all. Specialized processes ensure the right method for every instrument:

- Traceable calibration: Compares instrument measurements against certified, traceable standards to ensure regulatory compliance and legal metrology.

- Pipette calibration: Ensures medical and laboratory pipettes dispense accurate liquid volumes, critical for research and pharmaceutical applications.

- Torque wrench calibration: Guarantees correct force application in mechanical assemblies, preventing under-tightening or over-tightening that could cause failures.

- Load cell calibration: Validates weight measurements in scales and industrial processes, ensuring traceability and legal-for-trade status.

- Scale calibration: Adjusts and verifies all types of weighing scales, from laboratory balances to truck scales, for consistent accuracy.

- Multimeter calibration: Ensures electrical measurement tools (voltage, current, resistance) meet their specified accuracy for troubleshooting and diagnostics.

- Hardness test calibration: Validates the accuracy of instruments used to measure material hardness in manufacturing and materials science.

Types of Calibration Services include:

- On-site calibration: Performed at your facility, reducing equipment downtime and eliminating shipping risks.

- Laboratory calibration: Conducted in controlled lab environments, ideal for high-precision or sensitive instruments.

- Mobile calibration units: Bring calibration capabilities directly to your site for large-scale or distributed assets.

- Scheduled calibration maintenance: Ongoing service contracts to manage compliance and minimize risk.

- Remote calibration and support: Digital solutions for diagnostics, troubleshooting, and documentation.

Key calibration domains include:

- Pressure calibration service: For pressure switches, transmitters, relief valves, and barometers in both gas and liquid systems.

- Temperature calibration service: For thermocouples, RTDs, bimetal thermometers, IR meters, and thermal cameras.

- Humidity calibration: For humidity recorders, sensors, and thermohygrographs, ensuring accurate environmental monitoring.

- Flow calibration: For volumetric and mass flow meters, flow controllers, and process equipment.

- Electrical calibration: For oscilloscopes, multimeters, data loggers, and other instruments measuring voltage, current, or resistance.

- Dimensional calibration: For micrometers, calipers, height gauges, and other devices measuring physical dimensions.

- Force calibration: For devices measuring weight, torque, tensile, and compressive forces.

Searching for the best calibration service for your application? Use our directory to compare top providers by specialization, accreditation, and geographic coverage.

Benefits of Calibration Services: Why Invest in Regular Calibration?

Investing in professional calibration services delivers a host of benefits across every industry:

- Regulatory compliance: Meet the strict requirements of standards bodies (ISO, FDA, GMP, NIST) and avoid costly fines or shutdowns.

- Accuracy and reliability: Maintain the integrity of measurements, ensuring product quality and safety.

- Reduced downtime: Prevent unexpected equipment failures and minimize production interruptions.

- Cost savings: Catch and correct measurement drift early, reducing scrap, rework, and warranty costs.

- Enhanced reputation: Demonstrate commitment to quality and traceability to customers and auditors.

- Global trade and fair business: Ensure your products meet international measurement standards, supporting global commerce.

- Societal safety: Minimize measurement errors in critical areas like pollutant monitoring, food safety, and clinical diagnostics.

Did you know? Routine calibration is a proactive strategy—identifying and fixing issues before they impact your bottom line or reputation.

Calibration Services for Industrial and Specialized Uses

Industrial calibration services underpin quality, safety, and compliance in sectors such as:

- Food and beverage: Regular calibration of temperature sensors and colorimetry equipment is vital for food safety, hygiene, and compliance with FDA and HACCP standards.

- Engineering and manufacturing: Uncalibrated equipment leads to increased rejects, downtime, and reputational damage. Timely calibration ensures high product quality and efficient operations.

- Pharmaceuticals and biotech: Strict FDA and GMP regulations require precise calibration of pipettes, balances, temperature sensors, and environmental monitoring equipment.

- Aerospace and defense: Extreme precision in torque, dimensional, and environmental measurements is essential for safety and regulatory compliance.

- Energy and utilities: Flow, pressure, and electrical calibration safeguard critical process controls and reduce safety risks.

Need industry-specific calibration advice? Connect with a specialist who understands your sector’s unique challenges and regulatory environment.

How to Select a Calibration Service Provider?

Selecting the right calibration provider is a strategic decision that impacts your compliance, operational efficiency, and bottom line. Here’s a comprehensive guide to evaluating potential partners:

- Assess Technical Competence

- Industry experience: Confirm the provider has expertise with your equipment type, industry, and regulatory requirements.

- Service range: Ensure they offer all necessary calibration domains (e.g., electrical, temperature, torque, dimensional).

- Qualified technicians: Look for staff with ASQ CCT, manufacturer, or industry-recognized certifications.

- Verify Accreditation and Standards

- ISO/IEC 17025 accreditation: This ensures their lab is competent and their certificates are recognized globally.

- Traceability: Insist on calibration traceable to NIST, UKAS, or other national standards.

- Regulatory compliance: Ensure the provider can support your sector’s rules—FDA, AS9100, ISO 9001, etc.

- Evaluate Quality and Documentation

- Detailed certificates: Calibration reports should include before/after data, uncertainties, and environmental conditions—not just a sticker.

- Quality management system: ISO 9001 or equivalent indicates process maturity and reliability.

- Consider Logistics and Turnaround

- Location: Providers with on-site service or proximity to your facility can minimize equipment downtime.

- Turnaround time: Ask for standard and expedited service options.

- Equipment handling: Ensure safe transport, insurance, and experience with fragile or high-value instruments.

- Check Reputation and Support

- References and reviews: Request testimonials from similar industries and check online ratings.

- Customer support: Responsive technical support, proactive reminders, and troubleshooting add value.

- Cost versus value: Don’t choose solely on price—evaluate the full value proposition, including expertise and service quality.

- Look for Future-Ready Capabilities

- Digital tools: Providers offering cloud-based calibration reports, automated scheduling, and digital twins are positioned for future efficiency.

- Scalability: Choose a partner who can scale with your growing needs.

Practical Steps:

- Shortlist 3-5 providers through trade associations, directories, or search queries like “accredited calibration services near me.”

- Request detailed quotes, specifying equipment, standards, regulatory needs, and desired turnaround time.

- Visit their facility if possible to inspect their processes and equipment firsthand.

- Compare not just price, but also accreditation, expertise, and support.

Example: For a pharmaceutical plant requiring autoclave calibration, prioritize providers with ISO 17025 accreditation for temperature/pressure, experience in GMP environments, and on-site support. Review their documentation and ask for sample certificates.

Have questions about how to choose a calibration partner, or need help comparing providers? Contact our team or use our directory for personalized assistance.

Things to Consider Regarding Calibration Services

To maximize the value and reliability of your calibration program:

- Clearly define your needs—list equipment, required standards, budget, and whether you require on-site or off-site calibration.

- Use our directory to review reputable, accredited calibration companies with a proven track record in your industry.

- Contact 3-4 providers for quotes and technical discussions; document their responses and compare on expertise, compliance, and service scope.

- Assess their customer service and willingness to provide ongoing support, reminders, and troubleshooting.

- Choose a provider that balances technical rigor, documentation quality, responsiveness, and value for money.

Still unsure which calibration service is right for you? Use our easy search tool or contact us for tailored recommendations based on your application, regulatory needs, and location.

Frequently Asked Calibration Questions

- How often should my equipment be calibrated?—Intervals depend on equipment type, usage frequency, manufacturer recommendations, and regulatory requirements. Critical instruments may require monthly or quarterly calibration; others can be annual.

- What is ISO/IEC 17025 accreditation, and why does it matter?—This standard certifies that a calibration lab produces valid, repeatable results. It’s recognized globally and often required for regulated industries.

- What documentation should I receive after calibration?—A detailed certificate showing before/after data, standards used, measurement uncertainties, environmental conditions, and technician credentials.

- Can calibration be performed on-site?—Yes, many providers offer on-site calibration for minimal disruption, especially for large or fixed equipment.

- What are the risks of skipping calibration?—Uncalibrated equipment can lead to quality failures, compliance violations, product recalls, safety incidents, and substantial financial loss.

- What is traceability in calibration?—Traceability means every measurement can be linked to a recognized national or international standard, ensuring confidence in results.

Ready to schedule calibration or request a quote? Browse our list of top calibration service companies and take the next step toward measurement excellence.

What is a calibration device and why is it important?

A calibration device is a specialized tool that generates precise electrical signals to fine-tune and standardize the performance of instruments or equipment. Calibration ensures that devices operate within highly accurate, predefined parameters, which is crucial for measurement accuracy, regulatory compliance, and safety in industries like manufacturing, healthcare, pharmaceuticals, aerospace, and scientific research.

What is calibration traceability, and why does it matter?

Calibration traceability means that all measurements can be linked to recognized national or international standards, such as those from NIST or UKAS. This provides confidence in measurement accuracy and data integrity, which is essential for passing audits and maintaining compliance with regulations.

Which types of equipment and industries commonly require calibration services?

Calibration services are required for instruments such as load cells, scales, data acquisition sensors, temperature sensors, chemical sensors, strain gauges, automotive sensors, proximity sensors, optical sensors, barometers, and more. Industries ranging from logistics and manufacturing to laboratories, pharmaceuticals, food and beverage, aerospace, and energy utilize calibration to ensure accuracy and compliance.

How often should equipment be calibrated?

Calibration intervals depend on the equipment type, frequency of use, manufacturer recommendations, and regulatory requirements. Critical devices may need calibration monthly or quarterly, while others might only require annual calibration. Industry standards and specific applications play a significant role in determining the best schedule.

What should I look for when selecting a calibration service provider?

When choosing a calibration provider, check for technical competence, relevant industry experience, accreditation such as ISO/IEC 17025, traceability to national standards, comprehensive documentation, responsive customer support, and digital capabilities. Consider not just the price, but also the provider’s reputation, service range, and ability to meet regulatory demands specific to your industry.

What are the main benefits of regular calibration?

Regular calibration ensures regulatory compliance, measurement accuracy, and reliability. It reduces downtime, prevents costly errors or recalls, supports product quality, enhances reputation, and helps maintain societal safety in critical areas such as food safety and clinical diagnostics. Proactive calibration also minimizes financial and legal risks.

Can calibration be performed on-site, and what are the advantages?

Yes, many calibration providers offer on-site services, reducing equipment downtime and eliminating shipping risks. On-site calibration is especially useful for large, fixed, or sensitive equipment, allowing minimal disruption to operations and faster turnaround times.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services