Machines are used in various industries to perform a range of functions. However, the accuracy and reliability of machines can decrease over time, which can lead to erroneous results, downtime, or even accidents. This is where machine calibration comes in. Calibration is a process of adjusting and verifying the performance of machines to ensure that they operate accurately and within defined specifications. Read More…

Custom Calibration specializes in on-site and laboratory calibration which will keep costly equipment downtime to a minimum and maximize your overall productivity. We have over 30 years of experience providing calibration services for mechanical, dimensional, scale, torque, humidity, and many more applications. Our company’s mission is to achieve total customer satisfaction by providing prompt, ...

ISO/IEC 17025:2017 & ANSI/NCSL Z540.3 Accredited Laboratory. Electronic, dimensional, physical and thermodynamic calibrations performed onsite and in our lab. Professional ASQ Certified Calibration Technicians. We support the manufacturing and service sectors including; aerospace, automotive, chemical, electronic equipment, energy, food, industrial, machinery, medical, metal, military, nuclear,...

At MSI-Viking Gage, LLC, we are dedicated to providing industry-leading calibration services that are both comprehensive and adaptable to meet the diverse needs of our clients. With extensive ISO 17025 Accredited and ISO 9001 Certified calibration capabilities, we ensure that every measurement and calibration we perform adheres to the highest standards of accuracy and reliability. Our services...

Fox Valley Metrology provides calibration and repair services for various types of measuring instruments, including dimensional, electrical, and mechanical equipment. We have been in the industry for almost 30 years, serving clients across various industries, including aerospace, automotive, medical, and manufacturing. We aim to provide quality and accurate calibration services that meet or...

Standard Calibrations offers quality calibrating services, gage calibration services and more. We offer calibrating services that will handle your needs from the smallest meter to complete propulsion control systems. We have a calibration laboratory and pressure calibration devices to serve you.

At Advanced Measurement Streamlined Precision, we dedicate ourselves to delivering calibration services that ensure accuracy, reliability, and consistency across a wide range of instruments and equipment. We recognize that precise measurement is the backbone of any technical operation, and we approach each project with the goal of providing confidence in every reading.

Sierra provides accurate calibration services for mass flow meters and controllers, insertion thermal flow meters, vortex, and ultrasonic flow meters. With more than 40 years of expertise in gas, air, or liquid flow calibration, you can count on our team to make sure your flow meter operates with efficiency and pinpoint accuracy. We believe in providing personalized and customized service, and...

More Machine Calibration Manufacturers

Types and Processes of Machine Calibration

Machine calibration is a critical process in ensuring the precision, accuracy, and reliability of industrial and laboratory equipment. Calibration involves comparing the measurements of a device under test to a known standard, adjusting the device as necessary to meet required tolerances. Depending on the application and the type of equipment, there are several key categories of machine calibration:

- Dimensional Calibration: This calibration type is focused on verifying and adjusting the accuracy of linear and angular measurements. Commonly applied to coordinate measuring machines (CMMs), calipers, micrometers, and other measuring instruments, dimensional calibration is essential in precision engineering, manufacturing, and quality assurance settings. Looking for more information on dimensional calibration requirements for your industry? Contact our calibration specialists.

- Temperature Calibration: This process ensures that thermometers, thermocouples, temperature sensors, and environmental chambers provide accurate temperature readings. Temperature calibration is vital in food safety, pharmaceuticals, HVAC, and laboratory research. Learn how temperature calibration affects compliance with industry standards by browsing our temperature calibration providers.

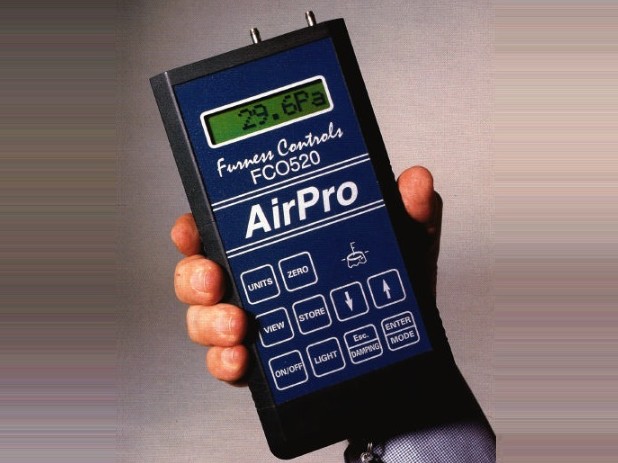

- Pressure Calibration: Used to verify the accuracy of pressure gauges, barometers, manometers, and transducers, pressure calibration is a necessity in industries such as oil and gas, automotive, and medical device manufacturing. Interested in pressure calibration protocols and best practices? Explore our knowledge base for step-by-step guides.

- Electrical Calibration: This type of calibration confirms the accuracy of instruments that measure electrical properties such as voltage, current, resistance, and frequency. Multimeters, oscilloscopes, and power analyzers commonly require electrical calibration. If you're searching for accredited electrical calibration laboratories, visit our directory for trusted providers.

- Additional Calibration Types: Other specialized calibration processes include mass calibration (for balances and scales), flow calibration (for flow meters and pumps), pH calibration (for laboratory meters), and torque calibration (for wrenches and torque sensors).

How often should machines be calibrated? The frequency of machine calibration depends on factors such as equipment type, usage intensity, manufacturer recommendations, and regulatory or ISO standards. For in-depth guidance, see our article on establishing calibration intervals.

Machines That Require Calibration

Nearly every industry relies on accurate measurement, making machine calibration a universal requirement. Below are some of the most common types of equipment that benefit from regular calibration services:

- Manufacturing Equipment: CNC machines, milling machines, lathes, and 3D printers require dimensional, temperature, pressure, and electrical calibration. These processes are essential for maintaining part tolerances, minimizing scrap, and ensuring product consistency. Are you benchmarking your manufacturing calibration schedule? Compare best practices here.

- Laboratory Instruments: Equipment such as pipettes, analytical balances, spectrophotometers, thermometers, and pH meters must be calibrated for temperature, mass, volume, and chemical accuracy. Laboratory calibration services help meet GLP, GMP, and ISO 17025 accreditation requirements.

- Medical Devices: Blood pressure monitors, ventilators, medical thermometers, infusion pumps, and ECG machines all require precise calibration to ensure patient safety and regulatory compliance. Calibration for medical equipment often follows guidelines from the FDA and international standards bodies.

- Aerospace Equipment: Altimeters, accelerometers, gyroscopes, and avionics systems demand rigorous dimensional, temperature, pressure, and electrical calibration. Aerospace calibration improves flight safety and supports compliance with FAA and EASA requirements.

- Automotive Tools and Equipment: Tire pressure gauges, engine analyzers, alignment machines, and emission testers depend on regular calibration to uphold vehicle safety and environmental standards. Automotive calibration also contributes to improved efficiency in diagnostic and repair operations.

- Process Control and Industrial Automation: Flow meters, pressure sensors, control valves, and transmitters are integral to automated production lines. Precision calibration ensures optimal process control, safety, and system uptime.

Curious about whether your equipment needs calibration? Take our interactive quiz or contact an expert to assess your calibration needs.

Considerations Regarding Machine Calibration

While machine calibration is essential for maintaining the accuracy and reliability of machines, there are crucial considerations to weigh before initiating a calibration program:

- Cost of Calibration: Calibration expenses may include service fees, equipment downtime, travel or shipping costs, and investments in calibration standards. For complex machinery or high-frequency calibration needs, these costs can be significant. Interested in reducing calibration costs? Explore proven strategies here.

- Time and Scheduling: Calibration can be time-consuming, particularly for equipment that must be taken offline for extended periods. Effective scheduling and planning are vital to minimize operational disruptions. Implementing predictive maintenance programs may help streamline calibration timelines.

- Technical Skill Requirements: Accurate calibration demands skilled technicians who are trained in metrology, uncertainty analysis, and industry-specific standards. Inadequate training can lead to human error, resulting in inaccurate calibration, equipment failure, or compliance violations. Are you looking to upskill your calibration team? See our recommended training programs.

- Calibration Traceability and Documentation: All calibration activities should produce traceable records that can be audited. Maintaining detailed calibration certificates and logs is critical for regulatory compliance and quality assurance.

- Environmental Factors: The accuracy of calibration can be affected by temperature, humidity, vibration, and electromagnetic interference. Controlling these variables in the calibration environment is crucial for reliable results.

Benefits of Machine Calibration

Investing in regular and precise machine calibration yields a wide range of operational and business benefits. Here are some of the most impactful advantages:

Accuracy and Precision

Calibration certifies that machines perform within their specified accuracy and tolerance levels. This results in higher product quality, reduced measurement uncertainty, and greater process reliability. For industries such as aerospace, pharmaceuticals, and automotive manufacturing, even minor inaccuracies can have significant consequences. Calibration ensures every measurement counts.

Regulatory Compliance

Many industries, including food and beverage, medical device manufacturing, and aerospace, are subject to stringent regulatory standards such as ISO 9001, ISO 17025, FDA, and EU MDR. Regular calibration provides documented evidence that equipment meets these standards, helping organizations avoid costly fines, recalls, and reputational risks. Need help navigating regulatory requirements? Consult our compliance resources.

Operational Efficiency

Calibrated machines operate more efficiently, minimizing unexpected downtime, maximizing throughput, and supporting lean manufacturing initiatives. Improved efficiency leads to increased productivity and higher profitability. Companies leveraging predictive maintenance in conjunction with calibration see even greater uptime improvements.

Cost Savings and Risk Reduction

By proactively calibrating machinery, organizations can identify and address deviations before they lead to costly breakdowns or product defects. This reduces the need for emergency repairs, lowers scrap and rework rates, and extends the lifespan of capital equipment. Explore our ROI calculator to quantify your potential cost savings.

Extended Equipment Life

Routine calibration exposes potential problems early, such as wear, drift, or environmental impacts. By addressing these issues promptly, you prolong equipment life, improve asset reliability, and defer capital expenditures on new equipment. Looking for asset management best practices? Read our guide to maximizing equipment lifespan.

Improved Workplace Safety

Safety-critical equipment, including pressure vessels, medical monitors, and industrial control systems, must be calibrated to ensure safe operation within specified limits. Accurate calibration reduces the risk of workplace accidents, equipment failures, and liability claims.

Enhanced Customer Satisfaction

Delivering products and services that consistently meet or exceed customer expectations is key to building brand loyalty. Calibrated machines help organizations maintain high quality standards, reduce customer complaints, and win repeat business. Want to discover how calibration impacts Net Promoter Scores (NPS)? Learn more here.

Competitive Advantage

Organizations that prioritize accurate machine calibration often outperform their competitors by achieving higher productivity, better compliance, and superior product quality. This focus on quality assurance can be a major differentiator in crowded markets.

In-house Calibration vs. Calibration as a Service

When considering how to implement a calibration program, organizations must decide between in-house calibration and outsourcing to a calibration service provider (Calibration as a Service or CaaS). Each approach offers unique benefits and challenges:

- In-house Calibration: This approach involves training internal staff and investing in calibration standards, reference materials, and controlled environments. In-house calibration can offer quicker response times and lower costs for high-volume or frequently used equipment. However, it requires significant upfront investment, ongoing training, and compliance with metrology standards such as ISO/IEC 17025.

- Calibration as a Service (CaaS): Outsourcing calibration to a third-party provider can provide access to accredited laboratories, specialized expertise, traceable results, and a wider range of calibration capabilities. CaaS providers often offer pickup and delivery, rapid turnaround, and digital recordkeeping. This model is ideal for organizations that lack internal resources or require calibration for a diverse set of equipment. Not sure which model fits your needs? Take our calibration decision assessment.

Which calibration approach is right for your business? Evaluate your budget, regulatory requirements, equipment criticality, and the volume of assets to make an informed decision.

Determining the Need for Machine Calibration

Knowing when to calibrate your equipment is essential to maintaining quality and reliability. Key indicators that a machine requires calibration include:

- Equipment Malfunction: Unusual readings, frequent errors, or inconsistent output often signal calibration drift or failure.

- Scheduled Preventive Maintenance: Many manufacturers recommend calibration at regular intervals—monthly, quarterly, or annually—based on usage and application.

- Regulatory or Audit Requirements: Compliance-driven industries may require calibration as part of routine audits, quality system certifications, or customer contracts.

- Environmental or Usage Changes: Relocating equipment, exposing it to extreme temperatures or humidity, or increasing operational cycles can necessitate more frequent calibration.

- Post-Repair or Modification: Any equipment that has been repaired, modified, or subjected to mechanical shock should be recalibrated before returning to service.

How can you tell if your machine needs calibration? Review your calibration logs, monitor for out-of-tolerance results, and consult with calibration experts for a risk assessment.

Contacting a Machine Calibration Service

When it's time to calibrate your equipment, finding a reputable calibration service provider is critical. Here are some proven methods to identify and select the right calibration partner:

- Online Search: Use targeted search queries such as “ISO 17025 accredited calibration service near me,” “calibration laboratory for medical devices,” or “industrial equipment calibration providers.”

- Referrals and Recommendations: Ask colleagues, industry peers, or equipment manufacturers for trusted calibration service referrals.

- Request for Proposal (RFP) Process: For organizations with complex or high-volume needs, issuing an RFP ensures you receive competitive bids and detailed service offerings.

- Reviewing Accreditation and Capabilities: Always verify that the service provider meets relevant accreditation standards (e.g., ISO/IEC 17025) and offers the specific calibration services your equipment requires.

Once you've shortlisted potential providers, negotiate contract terms covering the scope of work, pricing, turnaround time, calibration traceability, and after-service support.

Choosing the Right Machine Calibration Service

To achieve the best calibration outcomes, it's essential to compare several calibration service providers. Use our comprehensive directory of machine calibration services to review business profiles, areas of expertise, customer testimonials, and industry accreditations. Each provider has a dedicated profile page with detailed information and a contact form for direct inquiries or quote requests.

- Review each machine calibration service website using our patented website previewer to quickly learn what each company specializes in.

- Leverage our simple RFQ form to contact multiple machine calibration services simultaneously, saving you time and streamlining your vendor selection process.

- Evaluate customer feedback, compare turnaround times, and check for specialized services such as on-site calibration, emergency support, or digital calibration certificates.

Ready to get started? Contact our calibration experts for personalized recommendations or request a quote from top-rated calibration services today.

Frequently Asked Questions About Machine Calibration

- What is the difference between calibration and verification? Calibration adjusts instruments to match standards, while verification checks if measurements meet specifications without adjustment.

- How do I maintain calibration records? Use digital calibration management systems or logbooks to track calibration dates, certificates, and results for audits and compliance.

- Can calibration be performed on-site? Many calibration service providers offer on-site calibration for large or sensitive equipment, minimizing downtime and logistical challenges.

- What accreditations should I look for in a calibration provider? Look for ISO/IEC 17025, ANSI/NCSL Z540.3, or other relevant accreditations that demonstrate technical competence and traceability.

- How do environmental factors affect calibration? Variations in temperature, humidity, or electromagnetic interference can impact calibration accuracy. Calibrate equipment in controlled environments whenever possible.

- What industries most benefit from regular calibration? Aerospace, automotive, pharmaceuticals, food and beverage, medical devices, electronics, and energy sectors all rely on precise calibration for safety, compliance, and product quality.

Next Steps and Resources

Machine calibration is an essential part of quality assurance, operational efficiency, and regulatory compliance in today's advanced manufacturing and laboratory environments. Whether you're looking to implement a new calibration program, optimize your existing processes, or find a trusted calibration service provider, our resources are here to help.

- Download our comprehensive Calibration Program Checklist to assess your current practices.

- Read case studies on how leading companies improved quality and reduced costs through targeted calibration programs.

- Sign up for our newsletter to receive expert tips, industry updates, and exclusive offers from top calibration service companies.

- Access our library of calibration standards, best practices, and technical white papers for reference and training.

Still have questions? Connect with our team of calibration experts for personalized advice tailored to your industry, equipment, and compliance needs.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services