TLC Calibration Company

TLC Calibration CompanyRequest A Quote

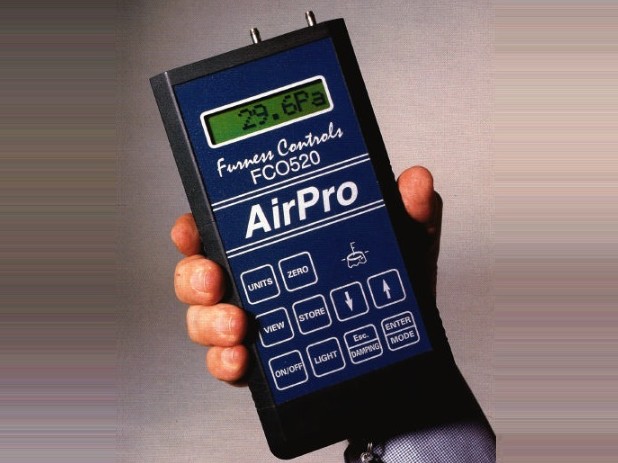

Mounds View, MNAt TLC Calibration Company, we provide comprehensive calibration services designed to support the highest levels of accuracy, reliability, and compliance across a wide range of industries. We specialize in the calibration of precision instruments, measurement devices, and testing equipment, ensuring that each tool we handle meets exacting standards and performs within specified tolerances. Our team is composed of experienced technicians and metrology experts who work closely with our clients to deliver calibration solutions that are both technically sound and tailored to their operational needs. We operate in a controlled laboratory environment equipped with state-of-the-art technology, allowing us to deliver traceable calibrations that conform to NIST standards and industry best practices. Whether we're working with pressure gauges, electrical meters, dimensional tools, or temperature sensors, our commitment to accuracy and documentation remains unwavering. In addition to our in-lab services, we offer on-site calibration support, minimizing downtime and maintaining productivity for facilities with sensitive or mission-critical equipment. Over the years, we’ve built long-term partnerships with clients in aerospace, manufacturing, healthcare, energy, and other sectors that depend on precise measurement to maintain safety, quality, and regulatory compliance. Our capabilities extend beyond calibration alone—we also assist with equipment certification, inventory management, and preventive maintenance planning to streamline our clients' quality assurance processes. With every project, we bring a deep understanding of metrology and a customer-first approach that has earned us a reputation for excellence and dependability in the calibration industry.

Leading Calibration Services Companies

More Calibration Services Companies

Additional Categories: Automation Equipment, AGV

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services